Tools are the backbone of any successful vehicle project. Whether you are in the garage at home or working in a professional shop, having the right tools ensures accuracy, efficiency, and safety. From diagnosing issues to installing high-performance parts, every job benefits from reliable equipment. In this guide, we share how to choose, install, and maintain tools for the best results.

A tool is any instrument or device used to perform a specific task. In the automotive world, tools can range from simple wrenches to specialized diagnostic devices. They make complex jobs possible, helping you work faster while reducing the risk of damage. The right tool not only makes the work easier but also improves the quality and precision of every job.

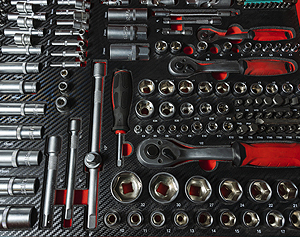

Automotive tools can be divided into categories such as hand tools, power tools, diagnostic tools, and specialty tools. Hand tools include sockets and wrenches, while power tools use electricity or compressed air to speed up the process. Diagnostic tools identify problems, and specialty tools handle unique repair tasks. Each category plays a role in keeping vehicles reliable and performing at their best.

A failing tool can cause delays, poor results, or even damage to your vehicle. Warning signs include rust, cracks, worn edges, or difficulty holding calibration. Power tools may overheat, make unusual noises, or lose power. Ignoring these signs risks both safety and precision. Regular inspection of your tools ensures they stay dependable and ready for the next project.

Selecting the right tools for your vehicle ensures repairs and upgrades are done correctly the first time. Consider your project’s needs, the type of vehicle, and your skill level. Quality matters, as precision tools prevent costly mistakes. Whether you work on daily drivers or performance builds, choosing the right tools saves time, money, and frustration in the long run.

OEM replacement tools are designed to match your vehicle’s original specifications, ensuring perfect fit and function. Performance tools, on the other hand, may offer enhanced durability, better grip, or faster operation. If you are working on high-performance applications, upgraded tools may be worth the investment. Understanding the trade-offs between OEM and performance options helps you make the right choice.

Before purchasing tools, confirm they are compatible with your vehicle’s make and model. Fitment matters for precision work, especially when dealing with torque specifications or tight clearances. Using tools that do not fit properly can strip bolts, damage parts, or cause safety hazards. Always check manufacturer guidelines and use fitment charts to ensure you are getting the right match. For instance, our lock ring tool is only compatible with the plastic lock rings used to fasten the fuel pump assembly to the fuel tank on many Polaris and Can-Am ATV/UTV vehicles; this tool would not be compatible with most other vehicles.

Tool assemblies combine multiple components into one functional unit, often streamlining complex jobs. Examples include complete socket sets, torque wrench kits, and brake service sets. Assemblies save time by providing all the pieces you need in one package, designed to work together seamlessly. For specialized automotive repairs, a well-built assembly can be a cost-effective and reliable solution.

Proper care of your tools extends their lifespan and ensures consistent performance. From tightening bolts to tuning engines, the way you use and store tools matters. Cleaning, lubrication, and correct storage help prevent wear and rust. In this section, we share guidelines, maintenance routines, and troubleshooting steps to keep your tools ready for every job.

When using new tools, start by reading the manufacturer’s instructions to understand the correct operating procedures. Follow torque specifications, use the right size for each fastener, and never force a tool into place. Applying too much pressure or using the wrong technique can damage both the tool and the part you are working on. Precision and patience are key.

Clean your tools after each use to remove grease, dirt, and debris. Lightly oil metal surfaces to prevent rust, and store tools in a dry, organized space. Calibrate torque wrenches regularly to maintain accuracy. For power tools, check cords, batteries, and moving parts for wear. A consistent maintenance routine ensures your tools stay in peak working condition.

If a tool is underperforming, first inspect it for visible wear or damage. For hand tools, check for cracks or worn gripping surfaces. For power tools, examine connections, batteries, and switches. Calibration issues can often be corrected with adjustment or servicing. Address problems early to prevent accidents and ensure you can complete projects without unnecessary downtime.

Upgrading your tools can make a noticeable difference in both efficiency and quality. Advanced tools often provide better ergonomics, higher precision, and increased durability. If you work on high-performance or specialty vehicles, having the right upgraded tools can make challenging tasks faster and more accurate. This section covers essential tool categories worth considering for an upgrade.

Basic tools are essential for everyday repairs, but upgraded versions often offer stronger materials, better grips, and more precise tolerances. A high-quality ratchet, for example, will have smoother action and last longer under heavy use. Investing in premium tools can improve your workflow, reduce fatigue, and deliver better results on every job.

When working on fuel systems, having the correct tools for pump installation and servicing is critical. This may include fuel line disconnect tools, pressure testers, and specialty sockets. Precision matters because improper handling can damage sensitive components. The right tools make the process cleaner, safer, and more efficient, especially in high-performance fuel pump installations.

Fuel line servicing requires specialized tools designed to prevent leaks and damage. Quick disconnect tools, hose cutters, and clamp pliers help ensure clean, secure connections. Upgrading to high-quality versions of these tools can improve sealing performance and make maintenance faster. The right tool can mean the difference between a safe repair and a costly fuel leak.

Comprehensive tool kits bring together a wide range of equipment in one organized package. These kits are ideal for mechanics who need versatility without constantly buying individual pieces. A good kit will include hand tools, specialty items, and sometimes power tools. By investing in a complete set, you are ready for almost any repair or upgrade project.

QFS was born from a desire for freedom: the freedom to keep your ATV, dirt bike, car, or truck running with dependable, OEM-quality, and affordable fuel systems. We want you back on the road without breaking the bank. Skip the costly dealership—our replacement parts ship directly to you and are easy to install. Enjoy OEM performance with unbeatable US-based support and a lifetime warranty. Are you with us?