Your vehicle’s fuel pump assembly plays a crucial role in delivering fuel from the tank to the engine with the right pressure and volume. Without it, your engine won’t receive the fuel it needs to function properly. This section introduces you to the basics of a fuel pump assembly and highlights why it’s essential for vehicle performance and reliability.

A fuel pump assembly is a complete unit that typically includes the fuel pump, strainer, float, and other components housed within the fuel tank. It ensures that fuel flows efficiently to the engine, maintaining consistent pressure for optimal performance. This all-in-one solution makes diagnosis and replacement easier compared to dealing with separate components.

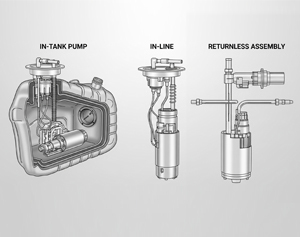

There are several types of fuel pump assemblies designed to meet different vehicle needs. Common types include in-tank, in-line, and returnless systems. Each one offers unique advantages depending on your engine configuration, fuel delivery method, and performance requirements. Understanding the differences helps in selecting the right assembly for your setup.

Common symptoms of a failing fuel pump assembly include difficulty starting the engine, engine sputtering at high speeds, loss of power under stress, and poor fuel efficiency. If ignored, these issues can lead to complete engine failure. Recognizing these signs early helps prevent breakdowns and costly repairs.

Selecting the right fuel pump assembly is critical for maintaining engine efficiency and longevity. Factors like compatibility, intended use, and quality of materials all play a role. Whether you're replacing a worn-out part or upgrading for performance, making an informed decision ensures reliable fuel delivery and peak engine performance.

When choosing a fuel pump assembly, you can opt for an OEM replacement or a performance upgrade. OEM replacements are ideal for daily drivers needing reliability and direct fitment. Performance upgrades, on the other hand, are suited for modified engines that demand higher flow rates and durability under stress.

Fuel pump assembly compatibility depends on the make, model, and engine type of your vehicle. Proper fitment ensures the unit works seamlessly with your vehicle’s fuel system. Always cross-reference part numbers and vehicle specs to avoid installation issues and performance problems down the road.

Fuel pump assembly kits often include everything needed for a hassle-free installation, such as filters, strainers, and tank seals . These complete kits are designed for convenience and reliability, helping you restore your fuel system quickly and efficiently. Choosing a high-quality assembly saves time and reduces the risk of future issues.

Proper installation and regular upkeep of your fuel pump assembly are essential for peak performance and long-term reliability. This section provides helpful guidance to make sure your new component runs smoothly from day one. With the right tools and a few simple checks, you can extend the life of your fuel system significantly.

Before installing a fuel pump assembly, always disconnect the battery and relieve fuel system pressure. Use OEM-compatible tools and follow the vehicle’s service manual. Ensure all seals and connectors are properly seated to avoid leaks or electrical faults. Installing a high-quality assembly correctly the first time prevents unnecessary future issues.

Regular maintenance of your fuel pump assembly includes checking fuel pressure, inspecting wiring connections, and replacing filters as recommended. Keeping your fuel tank clean and topped off helps prevent sediment buildup and overheating. These simple practices protect your investment and ensure dependable fuel delivery over time.

If your vehicle struggles to start, stalls under load, or shows fluctuating fuel pressure, your fuel pump assembly may need inspection. Check for clogged filters, faulty relays, or worn electrical connectors. Early diagnosis can prevent complete failure and save you from costly repairs or breakdowns.

Upgrading your fuel system goes beyond replacing a worn part—it’s about improving power, efficiency, and reliability. From a high-flow fuel pump assembly to complete kits, performance components are essential for modified engines and demanding driving conditions. Explore key upgrades to unlock your vehicle’s full potential.

High-performance fuel pump assemblies are designed to support increased horsepower and aggressive driving. These assemblies provide higher flow rates, durable materials, and precise pressure regulation. Whether for a street build or race application, upgrading your fuel pump assembly ensures your engine gets the fuel it needs.

Standalone fuel pumps offer targeted upgrades for both in-tank and external configurations. They’re a great choice for vehicles needing increased pressure or flow, especially when paired with turbocharged or supercharged setups. Quality fuel pumps improve combustion and overall drivability under load.

Upgrading your fuel injectors and lines complements a high-flow fuel pump assembly. Larger injectors deliver more fuel with precision, while reinforced lines maintain pressure and resist ethanol-related wear. Together, they ensure consistent delivery under high-performance conditions.

Fuel system kits bundle everything you need—fuel pump assembly, filters, injectors, lines, and pressure regulators—into one complete package. These kits are engineered for compatibility and ease of installation, making them ideal for serious builds or full system overhauls with guaranteed performance gains.

QFS was born from a desire for freedom: the freedom to keep your ATV, dirt bike, car, or truck running with dependable, OEM-quality, and affordable fuel systems. We want you back on the road without breaking the bank. Skip the costly dealership—our replacement parts ship directly to you and are easy to install. Enjoy OEM performance with unbeatable US-based support and a lifetime warranty. Are you with us?