Wiring is the backbone of every performance vehicle, yet it is often overlooked until something goes wrong. A single weak connection can determine whether a vehicle completes its run or fails midway. Wiring powers everything from the fuel pump to the sensors connected to the ECU. Selecting the right wiring improves reliability, maximizes performance, and ensures a vehicle is prepared for both competitive track use and challenging off-road conditions.

Wiring is the network that delivers steady and reliable power throughout a vehicle. It ensures that ignition systems, sensors, Fuel Pumps, and other components function as designed. Consistent electrical flow is essential for performance vehicles. Failures often occur not because of high-end upgrades but because wiring was neglected. A properly designed wiring system not only prevents breakdowns but also strengthens the foundation of the entire vehicle.

Different wiring types are engineered for specific roles, and selecting the correct one is vital. Primary wire is used for standard connections, sensor wire is intended for low-voltage signals, and high-current wire is built to power demanding parts such as pumps and fans. Using the wrong type can cause heat buildup, power loss, or even system failure. Properly matching wiring to its application supports consistent performance and system longevity.

Wiring problems often mimic other mechanical issues, making them difficult to diagnose. Warning signs include flickering gauges, intermittent power loss, burned connectors, or repeated fuse failures. In some cases, a fuel pump that cuts out under load may be caused by poor grounding rather than pump malfunction. Identifying and repairing faulty connections can restore system reliability and keep the vehicle performing at its best.

Selecting the proper wiring is not about using the largest gauge possible but about matching gauge, insulation, and layout to the specific demands of the build. Whether restoring an OEM setup or powering an 800-horsepower vehicle running on E85, wiring must withstand heat, vibration, and environmental exposure. Many otherwise strong builds have failed because wiring was overlooked. Making the right choices ensures long-term reliability under demanding conditions.

OEM wiring works well for standard daily driving, but performance applications require more. Additional fuel pumps, sensors, or electronics increase current demand and heat generation, which can exceed the limits of factory wiring. Upgraded wiring with larger gauge and high-temperature insulation provides the durability needed. In racing or forced induction applications, performance harnesses are recommended to ensure components remain dependable under extreme loads.

Wiring and connectors must be matched precisely to avoid weak points in the system. Using incorrect specifications can create resistance, reduce conductivity, and lead to premature failure. Before installation, it is essential to confirm that the harness is compatible with the fuel pump or module assembly. Direct-fit kits from Quantum Fuel Systems remove the guesswork, providing plug-and-play reliability and consistent performance.

Wiring assemblies simplify installation and increase reliability by combining multiple connections into a pre-configured harness. This approach reduces errors and minimizes the chance of miswiring. For multi-pump systems or custom setups, assemblies engineered by Quantum Fuel Systems are designed to meet the exact demands of modern fuel systems. Built from proven designs tested in high-performance environments, these assemblies deliver consistent results and trusted reliability.

Installing performance wiring is straightforward, but it is not an area where shortcuts can be taken. Every step matters, from protecting wires against heat to ensuring strong ground connections. Wiring should be viewed with the same importance as fuel delivery, since restrictions in current flow can cause issues similar to drops in fuel pressure. A properly designed system from the start delivers consistency, reliability, and peak performance.

Wire gauge must be matched to the current demand of each component. Use weatherproof connectors, heat-shrink tubing, and route wires away from heat sources or moving parts. Solid grounding is just as important as proper power supply, as weak grounds can cause voltage spikes that damage pumps, sensors, or ECUs. When working with O-ring or sealed plugs, apply a small amount of dielectric grease to protect seals and ensure long-term reliability.

Even the highest quality wiring requires regular inspection. Connectors should be checked for corrosion, voltage should be tested at the load, and insulation should be monitored for brittleness or wear. A voltage drop at the pump under load often indicates hidden resistance in the circuit. Tracing the wiring from the power source to the pump can identify these issues. Routine maintenance ensures wiring remains as dependable as the engine itself.

When a vehicle cranks but fails to start, or stalls under throttle, wiring should be one of the first areas inspected. Continuity testing with a multimeter and the proper wiring diagram helps eliminate guesswork. Many fuel pump failures are traced back to poor grounds or weak connections rather than faulty pumps. Restoring clean, stable electrical pathways often resolves performance issues without the need for part replacement.

Wiring upgrades are one of the most effective ways to improve fuel delivery, ignition accuracy, and system diagnostics. Stock wiring often limits performance, while upgraded harnesses ensure stable voltage across all components. Consistent power flow improves the function of fuel pumps, ECUs, and sensors. For those looking to protect their investment and maximize results, wiring upgrades are not optional but essential to achieving long-term reliability and peak performance.

Upgraded wiring provides more than increased load capacity. It ensures consistent power under demanding conditions. High-quality copper conductors, larger gauge sizes, and heat-resistant sheathing improve efficiency and reduce voltage drop. Whether supplying power to a 525LPH fuel pump or multiple aftermarket sensors, upgraded wiring maintains current flow without loss. This stability directly translates into stronger performance and dependable reliability.

High-flow fuel pumps require steady voltage to perform correctly. A drop of even one or two volts can reduce fuel flow and pressure, especially under boost conditions. Direct-fit wiring kits designed for high amperage loads provide the durability needed to meet these demands. Quantum Fuel Systems kits deliver consistent power to pumps, ensuring reliability both on the track and off-road, where stable performance is critical.

Wiring and fuel lines should be viewed as interconnected systems. Upgrading one without the other leaves weak links that reduce efficiency. Using ethanol-safe fuel lines alongside heat-shielded wiring creates a strong foundation for both fuel delivery and electrical performance. Proper routing away from high-temperature zones prevents degradation and extends service life. When both systems are upgraded together, vehicles achieve dependable operation across all conditions.

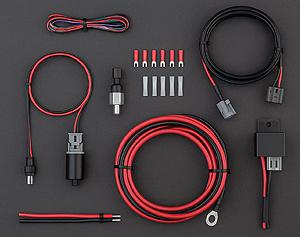

For full builds or restorations, comprehensive wiring kits provide everything needed in one package. These kits include connectors, sheathing, relays, and fuses, eliminating the need to source parts separately. Built from proven designs tested in demanding environments, they ensure reliability from installation onward. Starting with a complete wiring kit is the most efficient way to guarantee confidence and consistency throughout the build.

QFS was born from a desire for freedom: the freedom to keep your ATV, dirt bike, car, or truck running with dependable, OEM-quality, and affordable fuel systems. We want you back on the road without breaking the bank. Skip the costly dealership—our replacement parts ship directly to you and are easy to install. Enjoy OEM performance with unbeatable US-based support and a lifetime warranty. Are you with us?