Sensors serve as the eyes and ears of any performance vehicle, translating real-time conditions into data that the ECU uses for split-second adjustments. Whether maximizing horsepower or maintaining efficiency in a daily driver, sensors keep systems balanced and responsive. Accuracy is essential, as precise data ensures that every component operates in sync. In performance applications, dependable sensor readings often determine the difference between success and failure.

Sensors are critical monitors that measure variables such as fuel pressure, air flow, and temperature. This information is sent to the ECU, which immediately adjusts fueling, timing, and other parameters to keep the engine running at peak performance. Without accurate sensor data, even advanced setups cannot function properly. While they may not draw much attention, sensors are the unseen components that make reliable horsepower possible.

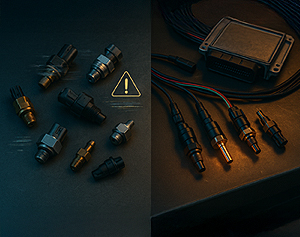

Different sensors work together to create a complete profile of engine operation. Oxygen sensors, MAP sensors, MAF sensors, and fuel pressure sensors form the foundation of this system. Knock sensors help prevent engine damage by detecting detonation, while temperature sensors provide predictive data for safer adjustments. High-performance builds often require specialized sensors, such as wideband O2 sensors and boosted MAP sensors, to deliver the precision needed for advanced tuning.

Failing sensors often create inconsistent or confusing symptoms. Common indicators include poor fuel economy, hesitation during throttle input, misfires, or an illuminated check engine light. In many cases, these issues stem from inaccurate sensor data rather than a mechanical failure. On both the dyno and the track, a single faulty signal can disrupt performance. If a vehicle feels unresponsive without a clear cause, inspecting sensors should be one of the first troubleshooting steps.

Precision and compatibility are critical when selecting sensors. OEM sensors are suitable for stock applications, but once an engine is modified or fuel types are changed, higher performance components become necessary. Cutting costs on sensors often leads to greater expenses later, as inaccurate readings can jeopardize engine health. Reliable data is essential for both performance and protection, making sensor choice one of the most important decisions in any build.

OEM sensors are designed to function within factory limits, making them ideal for unmodified vehicles. Performance builds, however, require sensors with greater accuracy, faster response times, and wider operating ranges. When running higher boost, using E85, or pushing high RPMs, upgraded sensors allow the ECU to react quickly and with precision. Beyond increasing power output, performance sensors protect engines from harmful conditions that OEM parts may not detect in time.

Not all sensors are interchangeable, and proper fitment is essential for accurate operation. Factors such as thread pitch, voltage range, and communication protocols determine whether a sensor will integrate with the system. Using the wrong component can result in incorrect data or total system failure. Choosing sensors designed for compatibility with both OEM wiring and aftermarket ECUs ensures reliable integration, eliminating guesswork and maintaining accuracy across the entire system.

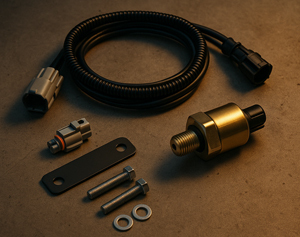

Sensor assemblies provide a complete solution by including connectors, wires, and mounting hardware in one package. This simplifies installation, reduces errors, and guarantees that each component works together seamlessly. Assemblies are particularly useful when adding fuel pressure sensors or equipping intake manifolds. By offering factory-level reliability with professional-grade performance, complete sensor assemblies save time while improving both accuracy and durability.

Installing sensors may appear straightforward, but a single loose connection or faulty ground can disrupt an entire system. Even one inaccurate reading can compromise performance or cause engine damage. Sensors require the same attention as critical components such as the fuel system. With correct installation and consistent maintenance, sensors provide the ECU with the reliable data it needs to protect the engine and deliver consistent performance.

Following basic guidelines ensures sensor reliability. Always torque sensors to the manufacturer’s specifications and apply the correct thread sealant, particularly on sensors exposed to oil or fuel. Confirm that connectors are fully seated, and route wiring away from heat sources or abrasive contact points. Mount MAP and boost sensors in an upright position to prevent condensation damage. After installation, verify readings through ECU logging software to ensure accurate data transmission.

Routine inspections keep sensors accurate and reliable. Check connectors for corrosion, especially after wet weather or off-road use. Secure wiring to avoid rubbing, pinching, or creating shorts. Certain sensors, such as wideband oxygen sensors, have a limited service life and should be replaced proactively to prevent sudden failures. Keeping sensors clean, properly mounted, and up to date ensures that the ECU receives dependable information for tuning and engine protection.

When a sensor displays unusual values, it should be tested before being replaced. Use a multimeter or ECU logging software to compare outputs against expected results. Fuel pressure sensors should align with readings from a mechanical gauge, and MAF outputs should increase in proportion to airflow. Many issues blamed on the ECU are actually caused by weak sensor signals. Replacing or verifying the sensor often resolves the problem and restores proper performance.

Sensor upgrades are more than monitoring tools; they unlock the full tuning potential of a vehicle. By providing the ECU with accurate, high-speed data, upgraded sensors allow for precise adjustments that keep engines safe and powerful. From refining fuel maps to protecting boosted applications from detonation, sensors play a critical role. Whether on the drag strip or daily driving, reliable sensor performance delivers both confidence and measurable results.

High-quality sensors provide sharper accuracy, faster response times, and higher resolution data. Wideband oxygen sensors, precision fuel pressure sensors, and advanced temperature sensors improve ECU feedback and tuning control. These upgrades allow the system to react faster, adjust more precisely, and strengthen fail-safes. Small inaccuracies can lead to significant performance losses, which is why dependable sensors are valuable in both high-performance racing and everyday driving applications.

The effectiveness of a sensor depends on the system it monitors, starting with fuel delivery. A fuel pressure sensor verifies whether the pump maintains steady output under load. Pairing advanced sensors with a high-flow Quantum Fuel Systems pump ensures stable performance by preventing pressure drops and lean conditions. This combination forms the foundation of consistent horsepower delivery and reliable operation across all driving conditions.

Upgrading sensors without upgrading fuel lines can create weaknesses in the system. For instance, flex fuel sensors require ethanol-safe lines and fittings to ensure durability and accurate readings. Using mismatched components may restrict flow or compromise data accuracy. When sensors and lines are properly paired, they work together to deliver consistent signals and stable system performance under any condition.

Comprehensive sensor kits streamline the upgrade process by packaging all required components into a single solution. These kits include high-accuracy sensors, plug-and-play connectors, and detailed installation guides, ensuring each part works seamlessly together. Designed and tested for real-world conditions, they provide dependable results for applications such as air-to-fuel monitoring or boost logging in turbocharged builds. A complete kit eliminates uncertainty and establishes a reliable foundation for performance tuning.

QFS was born from a desire for freedom: the freedom to keep your ATV, dirt bike, car, or truck running with dependable, OEM-quality, and affordable fuel systems. We want you back on the road without breaking the bank. Skip the costly dealership—our replacement parts ship directly to you and are easy to install. Enjoy OEM performance with unbeatable US-based support and a lifetime warranty. Are you with us?