Free Shipping

Buy Now, Pay Later

Guaranteed Fit

American Owned

Lifetime Warranty

U.S. Based support

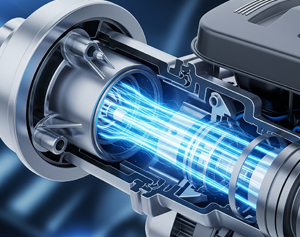

Performance fuel pumps are essential components designed to deliver precise fuel flow and pressure required by high-performance engines. Unlike standard pumps, these devices ensure optimal engine efficiency and increased horsepower by consistently supplying fuel at the required pressure, enhancing combustion quality. Ideal for both racing applications and enthusiast vehicles, a reliable performance fuel pump guarantees peak performance and long-term reliability in demanding driving conditions.

A performance fuel pump is an advanced, specialized pump engineered to meet the increased fuel demands of modified or high-performance engines. It maintains consistent, precise fuel delivery under high-pressure conditions, enabling enhanced power and acceleration. These pumps are critical for maintaining the proper air-fuel mixture necessary for optimal engine operation, improving overall engine efficiency, and ensuring reliable performance, particularly under strenuous conditions such as racing or off-road adventures.

Performance fuel pumps typically come in two main types: electric and mechanical. Electric pumps, commonly used in modern vehicles, provide consistent high pressure and volume, essential for fuel-injected engines. Mechanical pumps, driven by the engine itself, are commonly used in classic vehicles and racing applications requiring simplicity and reliability. Each type serves unique needs, with electric pumps generally offering higher performance capabilities, making them popular choices for enthusiasts seeking maximum efficiency and horsepower gains.

Recognizing a failing performance fuel pump early is critical to avoid potential damage to your vehicle. Common symptoms include difficulty starting, inconsistent engine performance, loss of power during acceleration, stalling at high temperatures, and abnormal noises from the fuel tank area. If you experience reduced fuel efficiency or observe inconsistent fuel pressure, these signs strongly indicate your fuel pump may be failing and requires immediate inspection and potential replacement to maintain optimal engine function.

Selecting the ideal performance fuel pump involves evaluating your engine's fuel demands, horsepower targets, and the specific fuel type used. Consider whether your application requires higher flow rates for boosted engines or compatibility with ethanol-blended fuels. Matching the fuel pump’s capabilities to your vehicle’s requirements ensures optimal performance, reliability, and efficiency, safeguarding your engine investment and enhancing your overall driving experience.

Deciding between OEM replacements and performance upgrades involves assessing your goals and budget. OEM fuel pumps offer exact fitment and original performance standards, making them suitable for general maintenance. Performance upgrades, however, provide enhanced fuel delivery, improved pressure handling, and increased reliability under high-demand conditions, making them ideal for those seeking improved engine performance and responsiveness in racing or heavily modified vehicles.

Ensuring compatibility and proper fitment of a performance fuel pump is vital. It’s essential to select a pump specifically designed for your vehicle’s make, model, and engine configuration. Proper compatibility prevents installation issues, potential fuel system damage, and guarantees the pump meets the engine's exact fuel delivery needs. Confirming these details beforehand eliminates potential downtime and ensures a smooth, efficient installation process.

Performance fuel pump assemblies are comprehensive kits that include all essential components such as the fuel pump, strainers, seals, wiring, and mounting hardware. These assemblies simplify installation, ensuring all parts are precisely matched for compatibility and performance. Investing in a complete assembly streamlines the upgrade process, reduces installation errors, and maximizes reliability and long-term performance gains in high-performance applications.

Proper installation and regular maintenance of your performance fuel pump ensure optimal function and longevity. Always adhere to manufacturer guidelines, using recommended tools and safety equipment. Regular inspection and upkeep prevent premature failures, optimize fuel efficiency, and help maintain consistent engine performance. Incorporating good maintenance practices significantly extends the service life of your fuel pump, safeguarding vehicle reliability and overall performance.

Accurate installation is critical for fuel pump performance. Always begin by thoroughly inspecting all components and ensuring cleanliness to prevent contamination. Use lubricant on O-ring seals for proper sealing. Follow specific torque specifications for fittings to avoid leaks. Verify electrical connections are secure, and check fuel lines for kinks or restrictions. Properly priming the pump before operation prevents potential damage and ensures optimal functionality from startup.

Routine maintenance significantly impacts fuel pump lifespan and efficiency. Regularly check and replace fuel filters to avoid blockage and pressure issues. Inspect fuel lines for leaks, wear, or corrosion. Monitor fuel pressure regularly to detect performance issues early. Using quality fuel and occasional fuel additives helps keep the system clean and free from deposits, enhancing pump performance and preventing costly repairs.

Recognizing and resolving common fuel pump issues promptly can prevent extensive damage. Typical problems include inconsistent fuel pressure, abnormal noise from the pump, and sudden performance drops. Always start troubleshooting by checking fuel pressure, electrical connections, and filters. Identify symptoms early, such as poor acceleration or difficulty starting, to facilitate timely interventions, ensuring optimal engine function and avoiding unnecessary downtime.

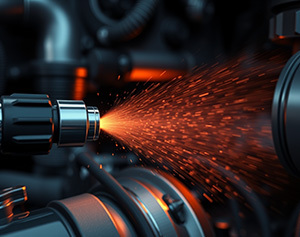

Fuel system upgrades can significantly boost your vehicle's performance, responsiveness, and reliability. Upgrading components such as fuel pumps, injectors, and fuel lines allows for better fuel delivery and increased engine efficiency. These enhancements support higher horsepower and torque outputs, providing improved throttle response and overall performance, particularly in competitive racing or high-demand applications.

Performance fuel pumps deliver higher fuel volume and pressure, critical for engines with increased horsepower demands. Upgrading to a performance pump ensures consistent fuel supply under demanding conditions, preventing lean mixtures and engine damage. These pumps are ideal for high-performance applications, offering improved reliability, durability, and sustained power delivery essential for racing and high-powered street vehicles.

Upgrading your standard fuel pump to a high-quality aftermarket pump enhances reliability and fuel system performance. These pumps provide stable fuel pressure, increased durability, and improved resistance to ethanol-based fuels, reducing the likelihood of vapor lock and pump failures. Upgraded pumps offer consistent performance, essential for maximizing power and efficiency, particularly under strenuous conditions.

High-performance fuel injectors and upgraded fuel lines are crucial for delivering increased fuel volume required by high-powered engines. Performance injectors offer precise fuel atomization, ensuring optimal combustion and improved efficiency. Upgraded fuel lines resist corrosion, withstand higher pressures, and reduce restrictions, providing the enhanced fuel delivery required for maximum engine performance and responsiveness.

Comprehensive fuel system kits provide all necessary components for upgrading your vehicle’s fuel delivery system. These kits include high-performance pumps, injectors, filters, regulators, and upgraded fuel lines, all matched to work seamlessly together. Opting for a complete system ensures compatibility, simplifies installation, maximizes reliability, and significantly enhances performance, meeting the demands of both racing and enthusiast-driven vehicles.

A performance fuel pump is designed to deliver higher flow rates and pressures compared to stock fuel pumps. If you've upgraded your engine or increased its power output, a performance fuel pump ensures that your fuel system can keep up with the increased demand. While a performance fuel pump can be installed in stock vehicles, it is typically overkill unless you're planning future upgrades.

The main difference is location: an external or in-line fuel pump is mounted outside the fuel tank, while an in-tank pump is located inside. External pumps are easier to access and replace, making them a popular choice for high-performance or custom setups, such as when using a universal fuel pump.

The primary difference lies in the flow rate. A 255lph fuel pump can deliver 255 liters of fuel per hour, while a 340lph fuel pump can deliver 340 liters per hour. Higher flow rates, such as those provided by the Walbro 255 fuel pump or the Hellcat fuel pump, are ideal for engines that require more fuel, especially in high-performance or forced induction applications.

Quantum Fuel Systems offers a full line of performance fuel pumps from their own brand (High Flow Fuel Pumps) but they also carry AEM, Bosch, and Walbro fuel pumps.

Yes, many high flow fuel pumps are compatible with E85 fuel. However, not all pumps are E85-safe, so it's important to choose a pump specifically designed for ethanol fuels. Check the descriptions and specifications for the pump you are considering to ensure its E85 compatibility. These pumps are built with materials that withstand the corrosive properties of ethanol.

The fluid you may find in your new Quantum fuel pump is testing fluid used during the manufacturing process to ensure the pump operates correctly under real-world conditions. We test pumps with fluid to check for proper flow, pressure, and functionality. This fluid is harmless and will not negatively affect your fuel system. It's completely safe to install and operate a pump that contains residual testing fluid.

When selecting a high pressure fuel pump, you should consider your vehicle's horsepower, fuel type, and engine modifications. For example, a 255lph fuel pump is a great choice for moderate horsepower builds, while a 340lph fuel pump is better suited for higher horsepower applications. Additionally, if you're using E85 fuel, ensure the pump is ethanol-compatible. Consult our guide for more information on choosing the right fuel pump for your horsepower goals.

A 255 fuel pump provides a higher flow rate than most stock pumps, making it ideal for performance upgrades. It's capable of supporting up to 500 horsepower on gasoline and is a popular choice for both naturally aspirated and turbocharged engines.

Discover our elite range of performance fuel pumps, engineered for enthusiasts who demand the best. Our selection features our in-house High Flow Fuel Pump line and other top brands like Walbro, AEM, and Bosch. These high-performance fuel pumps are designed to deliver the high flow rates necessary for maximum power, with options ranging from 255 LPH to 525 LPH, ensuring your vehicle is ready for any challenge. Whether you're running on E85 or traditional fuels, our E85-compatible fuel pumps provide consistent performance and durability. Ideal for high-powered builds, including Hellcat conversions, these pumps ensure your engine receives the fuel it needs, even under extreme conditions. Upgrade to a 340 LPH, 450 LPH, or higher capacity pump to support your high-volume fuel demands and experience unparalleled performance.

QFS was born from a desire for freedom: the freedom to keep your ATV, dirt bike, car, or truck running with dependable, OEM-quality, and affordable fuel systems. We want you back on the road without breaking the bank. Skip the costly dealership—our replacement parts ship directly to you and are easy to install. Enjoy OEM performance with unbeatable US-based support and a lifetime warranty. Are you with us?